pickup

[Materials for the Future]

- Battery component materials

Next-generation resin current collector

Features: “Can be used as current collector foil for batteries”

- It can be used as a current collector material for cylindrical, prismatic, and laminated cells.

Product specifications

| Current Collector | Anode | Cathode |

|---|---|---|

| Film Type | PET, PP, PI Base Film | |

| Film Thickness | 3.5 μm to 12 μm | |

| Conductive Coating Layer | Copper | Metalized AL |

| Coating Thickness | Up to 1 μm | |

| Product Width | Up to 1,000 mm | Up to 1,600 mm |

| Carbon Coating | Possible | |

| Carbon Coating Thickness | Up to 1 μm | |

| Coating Area | Any Pattern Carbon Printing (full, intermittent, stripe) | |

| Supply Status | Roll to Roll | |

| Core Size | 3 inch PP , ABS core | |

| Country of Origin | Made in China | |

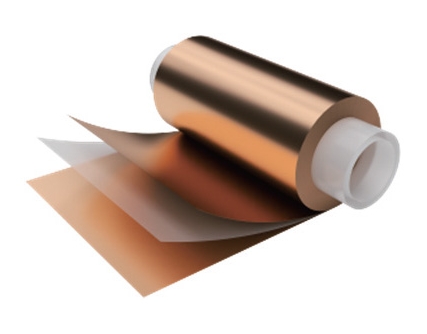

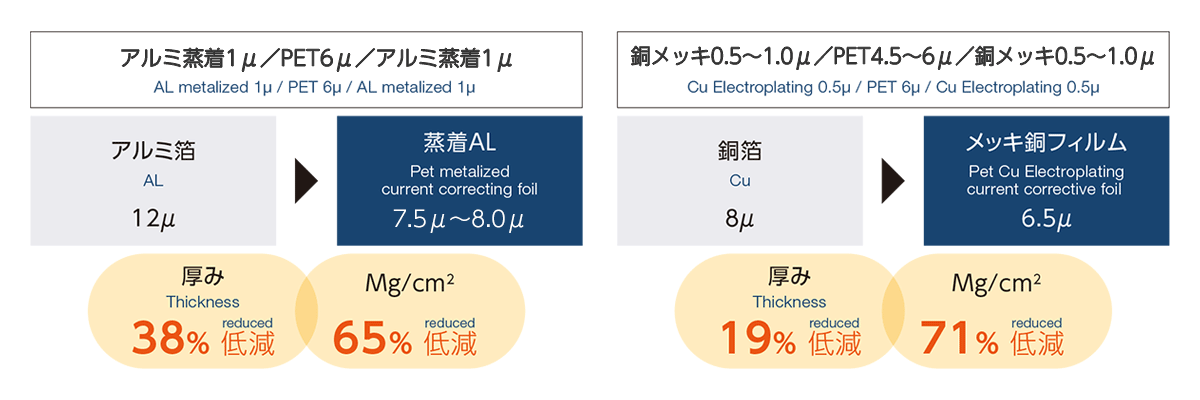

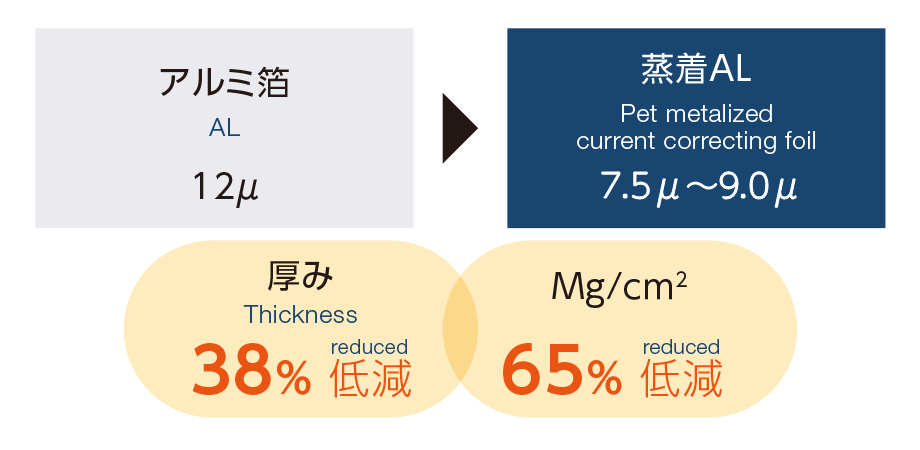

COMPOSITE ALUMINUM FOIL & COPPER FOIL

Cathode and Anode

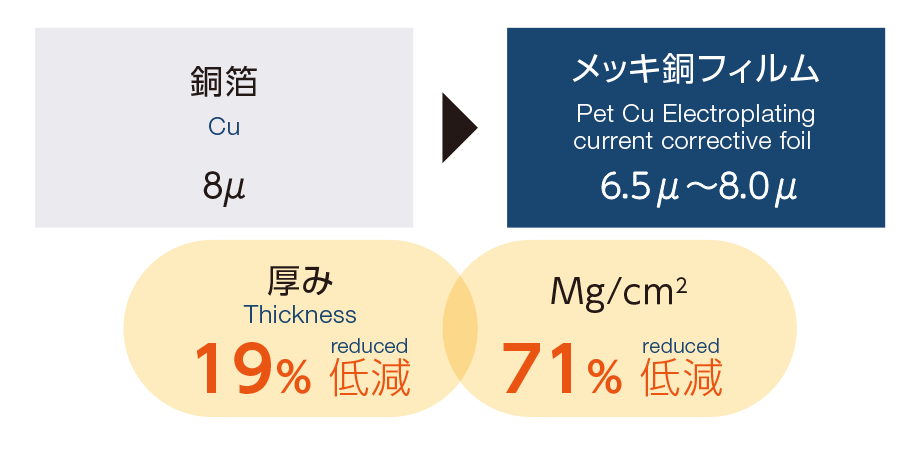

Changing the current collector from metal foil to film (vapor deposition or plating) leads to weight reduction and cost savings.

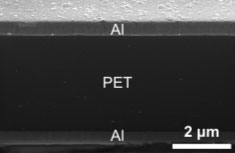

CARBON COATED COMPOSITE ALUMINIUM FOIL

| Carbon Coat0.5micron |

| Vacuum Metalized AL1micron |

| PET6micron |

| Vacuum Metalized AL1micron |

| Carbon Coat0.5micron |

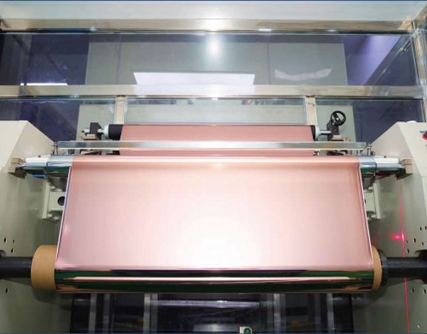

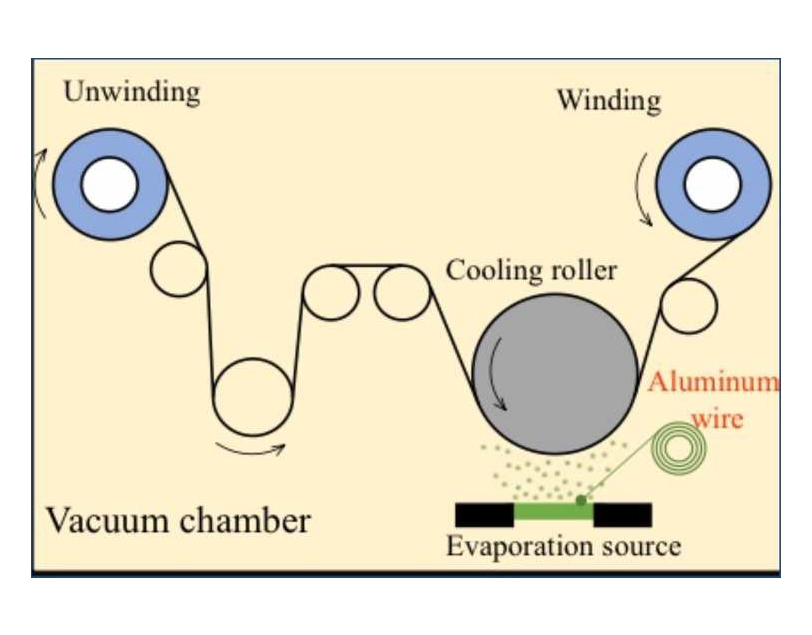

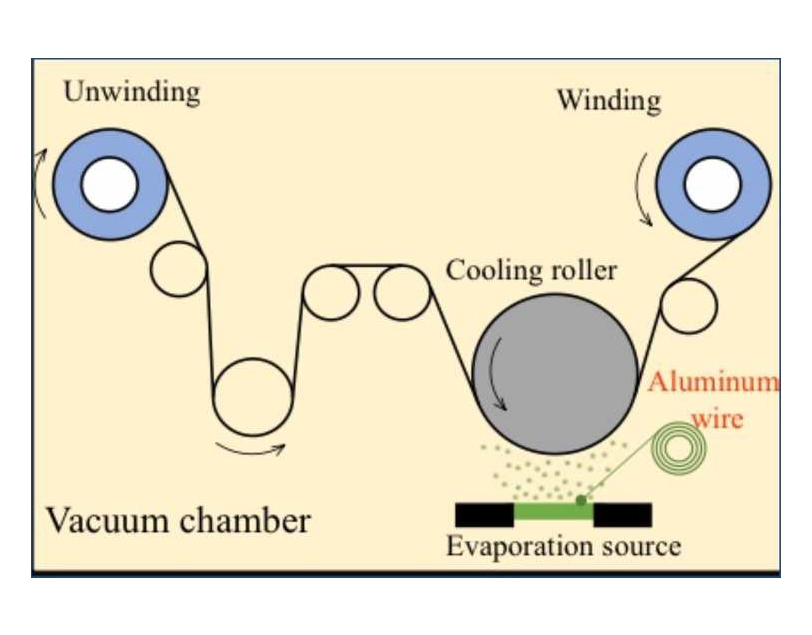

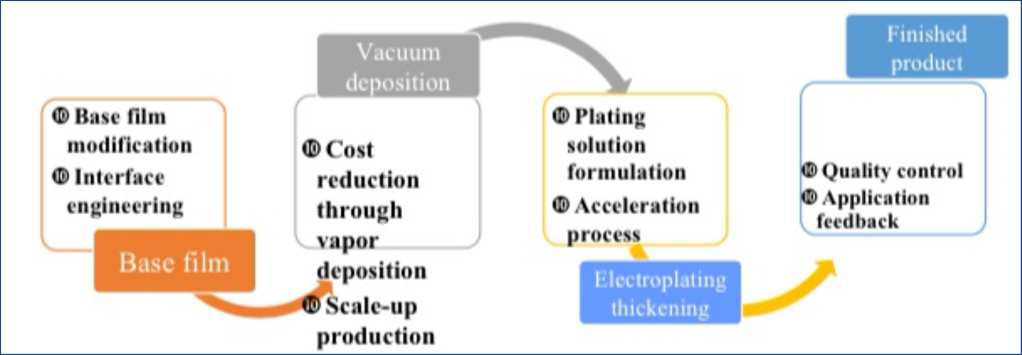

COMPOSITE ALUMINIUM FOIL PRODUCTION Vacuum Metalized AL production Process

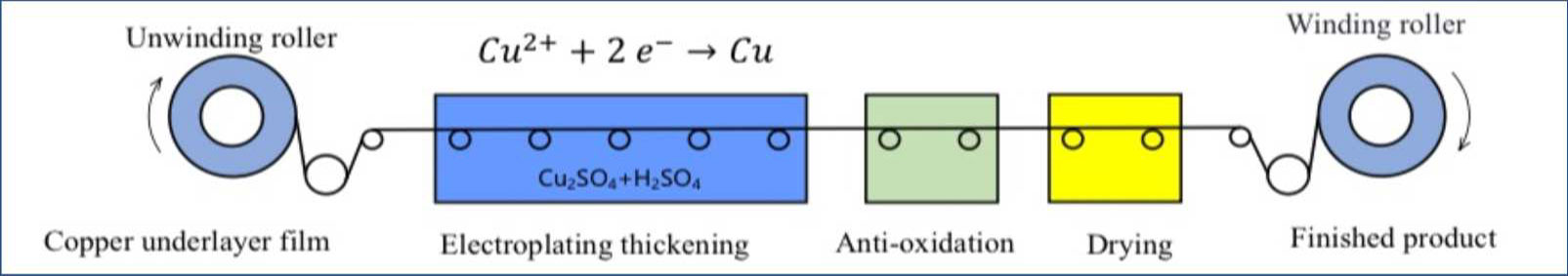

COMPOSITE COPPER FOIL Electroplating COPPER PET

| Electroplating Cu1micron |

| PET6micron |

| Electroplating Cu1micron |

COMPOSITE ALUMINIUM FOIL PRODUCTION Vacuum Metalized AL production Process

Electroplating COPPER production Process

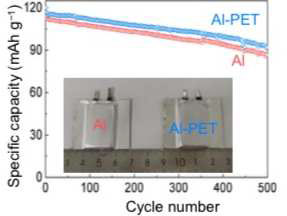

Performance Evaluation

COMPOSITE ALUMINIUM FOIL PRODUCTION Vacuum Metalized AL production Process

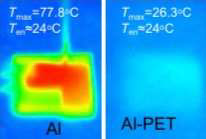

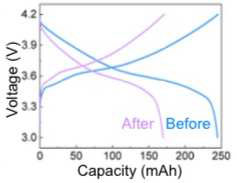

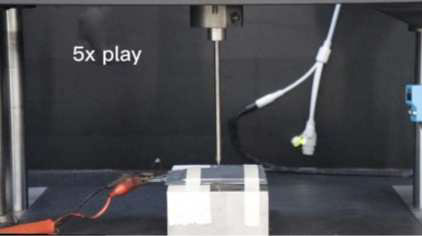

Performance Evaluation(Nail Penetration Test) NMC811 (5Ah High Nickel 811/Silicon Pouch battery)

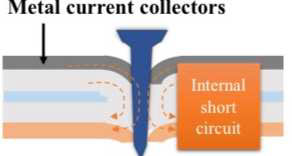

Aluminium Foil Battery Open Flame explosion. Aluminium Foil Battery Internal short circuit.

Composite Current No Fire Show in Battery Flame. Composite Current Collectors No Short Circuit.

Performance Evaluation (Nail Penetration Temperature Rise Comparison)

COMPOSITE ALUMINIUM FOIL PRODUCTION Vacuum Metalized AL production Process